Maintaining hygiene in food factories is not only a regulatory requirement but also a fundamental necessity to ensure consumer safety and product quality. This segment of factory maintenance includes the cleanliness of surfaces, equipment, and the entire facility, playing a crucial role in preventing contamination and maintaining hygiene protocols.

Regular and thorough cleaning and disinfection help eliminate pathogenic microorganisms that can cause foodborne illnesses and prevent product spoilage.

Read also: What is Sick Building Syndrome and is it present among your employees? >>

Maintaining hygiene in food factories – A detailed guide

Cleaning surfaces and equipment

Effective cleaning begins with understanding the various surfaces and equipment within the facility. Stainless steel, often used for its durability and corrosion resistance, requires specific cleaning methods to avoid damage.

Surfaces that come into contact with food, such as worktables, processing equipment, and packaging machines, must be regularly disinfected with approved detergents and disinfectants.

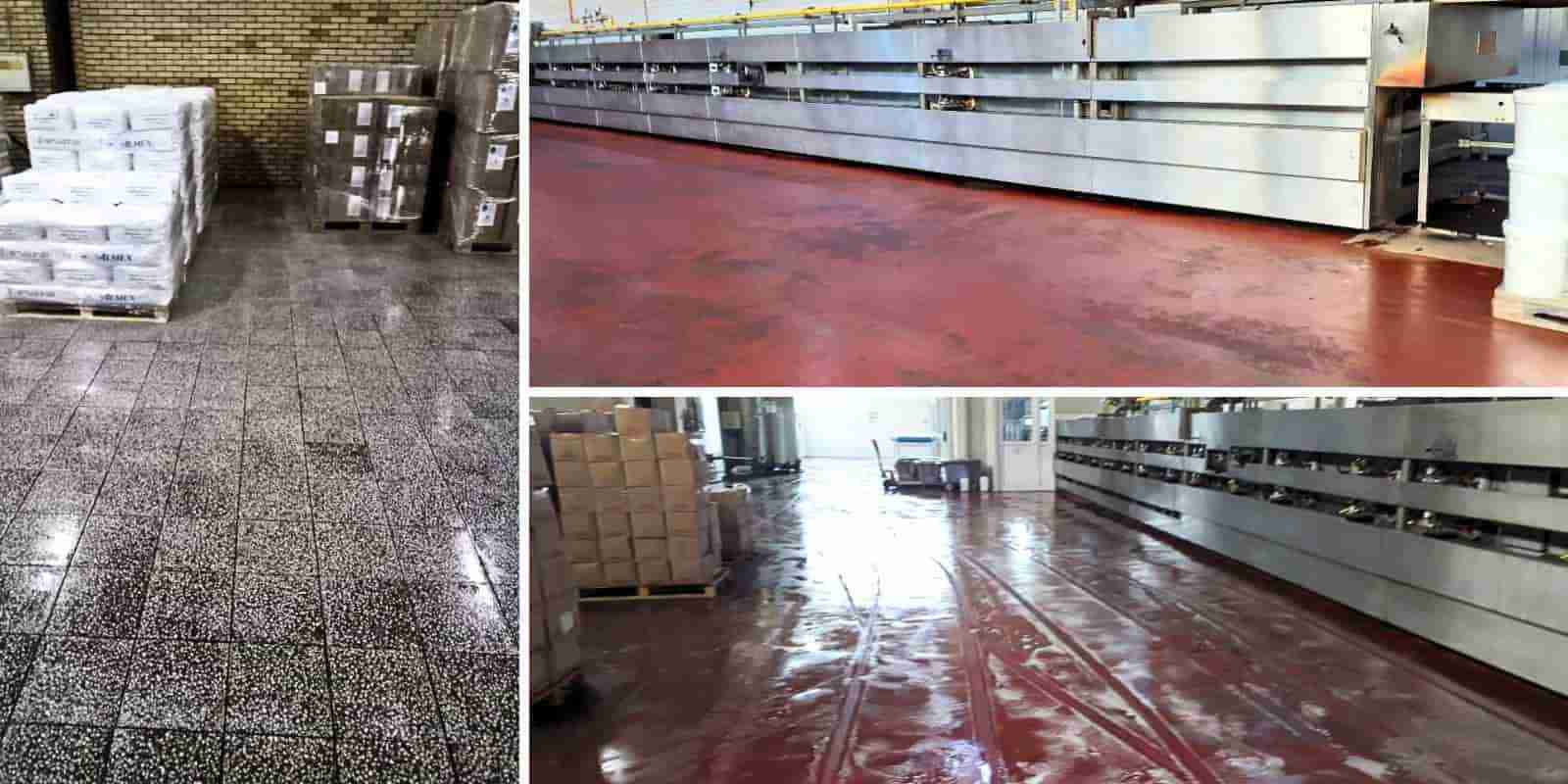

Maintaining hygiene in food factories also includes cleaning floors, walls, ceilings, and ventilation systems. Contaminants on these surfaces can indirectly contaminate food. That’s why removing grease with extra-strong degreasers is the first step in protecting nutritional substances.

Read also: The future of maintenance of business facilities >>

Cleaning methods

Food factories typically use a combination of manual and machine cleaning. Maintaining hygiene in food factories through these combined methods contributes to product safety and reduces the risk of contamination.

Manual cleaning involves thorough scrubbing and rinsing to remove visible dirt and residues from various surfaces. This is particularly important for hard-to-reach areas where food residues can accumulate or for restrooms. It is necessary to provide dispensers for napkins, toilet paper, soap, and disinfectants in these areas.

Machine washing and polishing of hard floors are effective ways to maintain their cleanliness and shine. This methods use specialized machines that combine washing, scrubbing, and polishing functions.

First, the floors are washed using rotating brushes and appropriate cleaning agents to remove dirt, stains, and grease. Then, a polishing process is applied using abrasive pads or discs to restore the surface’s shine.

Maintaining hard floors in this way extends their lifespan, reduces replacement costs, and ensures an aesthetically pleasing appearance. Machine washing and polishing are suitable for various types of floors, including marble, granite, ceramic, and vinyl. Regular cleaning is recommended, depending on the level of use of the space.

Read also: Machine washing of hard floors in the hands of professionals! >>

Frequency and specifications

The frequency of cleaning varies depending on factors such as production schedules, types of processed food, and regulatory requirements. High-risk zones, including raw material storage and processing areas, require daily cleaning. Equipment used for products sensitive to allergens undergoes more frequent cleaning to prevent cross-contamination.

Regular inspections and testing verify the effectiveness of cleaning procedures, ensuring compliance with hygiene standards.

Maintaining hygiene in food factories also requires consistent adherence to these procedures, including monitoring and documenting all cleaning activities.

Staff training and hygiene practices

Trained staff is crucial for maintaining sanitary standards. Cleaners must follow strict hygiene practices, including wearing appropriate protective clothing (hairnets, gloves, and protective coats) to prevent external contamination.

Training programs educate staff on proper cleaning techniques, chemical handling, and the importance of maintaining a clean environment during their shifts. Maintaining hygiene in food factories depends on well-trained and disciplined staff who understand and implement all hygiene procedures. Regular training and knowledge renewal are key to ensuring that staff are always informed about the latest hygiene standards and techniques.

Read also: Cleaning of factory and factory area maintenance >>

What else does Invekta pay attention to when maintaining hygiene in food factories?

Environmental control

In addition to equipment and surfaces, environmental factors impact hygiene. Controlling temperature and humidity in production areas prevents microbial growth and maintains product integrity. Air filtration systems minimize airborne contaminants, which is crucial in facilities handling sensitive products or allergens.

Hygienic maintenance of food factories includes monitoring these key environmental factors, as improper control can lead to food contamination. Regular maintenance of HVAC systems, checking filters, and ensuring adequate ventilation are key elements in controlling air quality in production areas.

Read also: What is an HVAC system and why is it important that it always works like clockwork? >>

Documentation and compliance

Compliance with hygiene regulations requires careful documentation. Cleaning schedules, inspection reports, and records of chemical use must be kept and available for audits.

Regulatory bodies regularly conduct inspections to check adherence to sanitary standards, where non-compliance can result in fines or shutdowns. Maintaining hygiene in food factories involves strict record-keeping. These records also help identify areas for improvement and provide evidence of compliance with legal and industry standards.

Maintaining hygiene in food factories – Continuous improvement

Achieving and maintaining high hygiene standards is an ongoing commitment. Continuous improvement involves adopting new technologies, improving cleaning protocols, and following best industry practices. Collaborating with suppliers of sanitary products and industry peers facilitates the exchange of knowledge and innovations in hygiene management.

Proper sanitary maintenance of the factory premises and production plant depends on continuous commitment and improvement. Investing in research and development of new cleaning methods allows factories to continually improve their hygiene standards and practices. In this sense, the implementation of feedback from staff and inspectors is also very important.

In conclusion, cleaning food factories is a complex process that requires strict adherence to protocols, investment in appropriate equipment, and ongoing staff training.

Prioritizing hygiene and compliance ensures that food factories maintain the safety and quality of their products, gaining the trust of consumers and regulatory bodies.

From this perspective, maximum hygienic correctness is not only an obligation but also a key component of the success and reputation of any food manufacturing factory.

With Invekta as a partner, you can make a positive impact and contribute to spreading good word not only about your products but also about the working conditions in your factory. This way, you will contribute to building a strong structure of quality staff that you can always rely on. Just like you can rely on us.

A quote request is at your disposal. As well as our phone number (+381 64 70 595 39) and email address (office@invekta.rs).

And don’t hesitate: we know that serious work happens in the factory, with the focus on producing quality food, not on the latest flashy interior. There are no unknowns or reluctance in our approach – we will scrub every corner of your factory so that it shines and smells of cleanliness.

Read also: Modernize and improve your business with software management! >>

0 Comments